Our conventional division offers a full array of e-line mechanical and logging services. Our highly trained managers and supervisors are equipped to handle all your completion and abandonment requirements.

Our perforating and mechanical services can be wireline conveyed on vertical wells and on horizontal well applications via wireline pump down, wireline conveyed tractor tool or convey on jointed or coil tubing.

Boreal Conventional E-Line has a full range of pressure control equipment (PCE) ranging from 7 MPa (1K Psi) to 103 MPa (15K Psi) allowing us to confidently service our customers no matter their pressure control needs.

We routinely update and certify our PCE to comply with stringent industry standards. Our team also maintains annual training and certificates necessary to properly operate the PCE safely and confidently during all e-line operations.

NOTE: 10K Psi / 68 MPa and 15K Psi / 103 MPa PCE available upon request

Our full complement of standard E-line logging tools can determine: cement bond, formation porosity, formation matrix, bed boundary delineation and casing collar identification. These tools are operated by our well-trained managers and supervisors, ensuring the data collected is accurate.

The retrieved data is transmitted to our expert team of log analysts and log processors in Calgary for further evaluation and interpretation. We also make sure to follow up with our customers to ensure complete comprehension of the results and make recommendations where required.

We understand the complex issues a surface casing vent flow (SCVF) or gas migration (GM) can pose for our customers when it comes to the final well abandonment. It is why we’ve committed significant resources over the past five years to solving these issues.

How? By building two specialized fiber-optic wireline units dedicated to running the HiFi MiCro Fiber Optic Directional Noise tool in combination with the Cased Hole Analysis Tool (CHAT) and Radial Cement Bondlog Tool (RBT).

With these tools at our disposal - combined with our highly-trained logging specialists and experienced team of log analysts- we confidently provide the answers required to re-solve these challenging SCVF and GM issues.

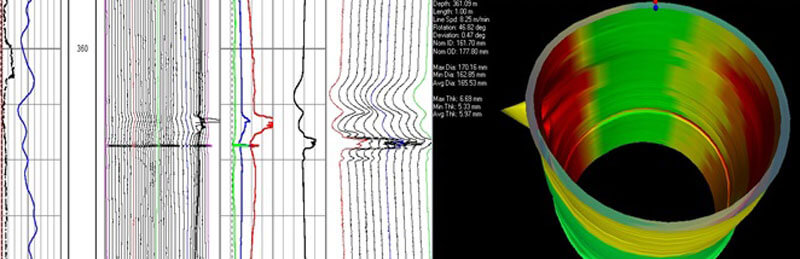

Our customers need immediate information regarding their tubing and casing issues. That’s why we use both GE/Sondex and GoWell technologies to help locate casing anomalies - from deformation and mechanical wear to corrosion monitoring.

By using these casing inspection technologies, we have the unique ability to evaluate multiple strings of casing simultaneously, through a broad range of casing sizes from 60.3 mm to 473.1 mm. Our specialty supervisors receive custom training to use these technologies to ensure accurate and quality data is recorded on every casing inspection job.

We understand that our customers require immediate information regarding reservoir performance data in a single run. That’s why we’ve chosen a comprehensive suite of GE/Sondex and and Lee-DataCan production logging tools: so we can economically evaluate and accurately measure key production parameters such as temperature, flow (spinners), capacitance, fluid identification (density) and pressure measurements.

Along with these key reservoir measurements, we work closely with our customers to design production logging programs to optimize and obtain accurate results specific to their logging needs.Upon completion of the logging program, a detailed evaluation of the data is formatted into a final report.

Not sure which solutions are right for you? Connect with a Bonnetts expert today.

Contact Us